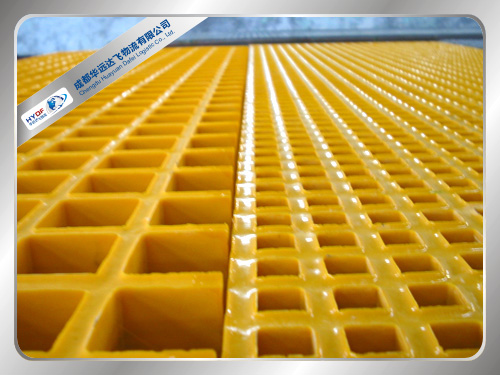

FRP Grating

FRP Grating is produced by wet moulding and hot curing in a heated mould. The reinforcement consists of continuous fibreglass rovings in alternating layers. So the loads are distributed evenly in all directions.

Regularly Moulded GRP Gratings have a polyester resin matrix. Glass content is approximately 35%. Standard colours are green, yellow or grey, other colours are available according to RAL.

Technical Parameters

|

Mesh size (mm) |

Standard Panel Size(mm) |

Thickness (mm) |

Weight (kg/m2) |

|

38*38 |

1220*4080 |

25 |

12.3 |

|

38*38 |

1220*3660 |

30 |

14.6 |

|

38*38 |

1220*3660 |

38 |

19.5 |

|

40*40 |

1007*4007 |

40 |

19.2 |

|

50*50 |

1200*3660 |

50 |

23.7 |

|

50*50 |

1200*3660 |

63 |

28.8 |

|

83*83 |

1007*4047 |

25 |

5.8 |

|

19*19/38*38 |

1220*4000double layer |

25 |

16.8 |

|

20*20/40*40 |

1007*4047double layer |

30 |

18 |

|

20*20/40*40 |

1007*4047double layer |

40 |

23.7 |

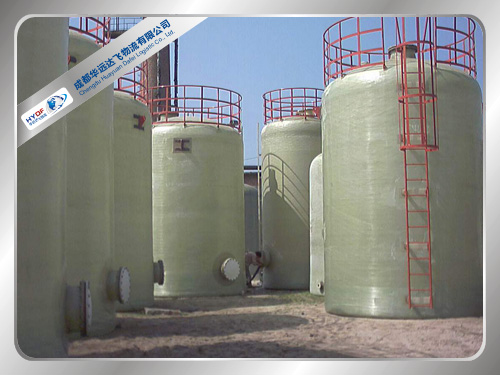

Excellent phthalate & isophthalic resin and surface veil mat is adopted, which make it possesses good corrosion property.

1,Light weight

Its weight is one quarter of steel gratings; easy for carrying, which reduce the carrying cost.

2,Good mechanical property

Resin content is 35%; fiberglass content is 65%, which increase the rate between strength and weight.

3,Aging resistance

UV absorption agent and polyester surface veil mat are added in the formula, which can protect from ultraviolet rays.

4,effective

The fire retardant effect isof1 class 25, or oxygen index is above 26.

Oxygen index can reach above 26. (per the requirement of project)

5,others

Impact resistance, free from maintenance, easy for processing, slide resistance, electric and thermal insulation.

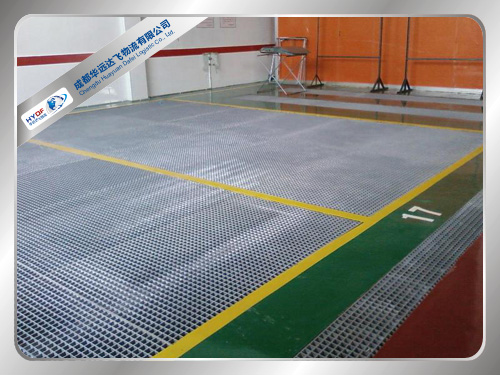

Installation on platform:

1) The width of support on steel beams of grating shall be at least 40mm, the gap between gratings shall be 6mm.

The gap between grating and concrete column is 10mm.

2) The gap between grating and supporting steel beam shall be fixed by M or L shaped clamp. At least 4 clamps need to be used for one piece of grating. Two adjacent edges of useless gratings shall be connected by C shaped clamp. At least one clamp shall be used in the center of every 1.8m.

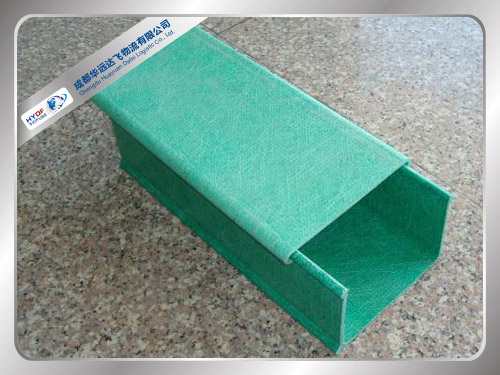

Installation in channels:

1) Adjust the size of channel refer to the size of each unit as possible as you can, which make the edge of grating after cutting to be the sealing face, ensure the integrity of units, and beautiful appearance.

2) 40mm support shall be added to the gratings on the concrete foundation; the gap between grating and concrete is 3-6mm.

Installation on stairs:

1) The step of grating shall be in the step frame; the frame can be normal steel or FRP.

2) Gap between step and frame is 3-6mm; 4 fixing clamps are used for each step; 1 for one corner.

3) The types of the clamps supplied by our company are: M, L, and C. different type clamp has different functions: M type is used for the fixing connection between grating and supporting structure; L type is used for special limited connection between grating and supporting structure; C structure is used for connection between edge and edge of gratings. Corresponding bolts and gaskets are needed the connection.

Maintenance:

Washing liquid can be used to clean the dust and dirties on the surface, no need of other maintenance measures.

Avoid direct connection with naked fire and high temperature, such as electric welding.

Avoid the drag and impact damage from any steel, steel sharp tools, and the painting pollution.