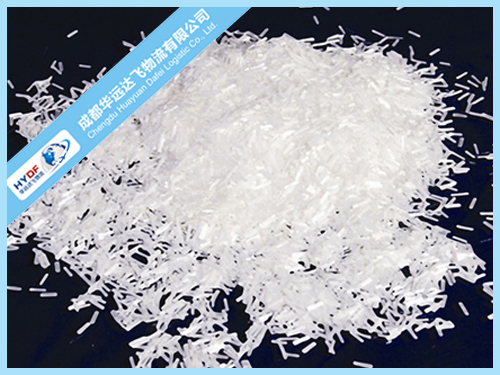

AR GLASSFIBER CHOPPED STRAND

AR GLASSFIBRE CHOPPED STRAND is a high integrity AR fiberglass chopped strand designed for use in dry mix systems or other premixing processes for subsequent moulding into a GRC component.

This kind of chopped strand has a sizing system optimized for abrasion resistance and strand integrity during blending with dry materials .The low-tex strand permits efficient reinforcement at low dosages .It is particularly suited to the preparation of pre-bagged mixes of special mortars or renders .It may also be used in the manufacture by pre-casting of standard GRC components.

Example: ARC15-98-12mmL(H)

AR: Alkali Resistant

C: Continuous fiber

15: Filament diameter

98: Tex of strand

12mm: strand length available

L: ZrO2 content 14.5%

H: ZrO2 content 16.7%

Properties

1. Good liquidity and integrity

2. Excellent alkali resistant and durability

Technical Characteristics

|

Tex of strand(tex) |

Sizing content(%) |

Moisture(%) |

|

98±10 |

1.6±0.2 |

≤0.2 |

Products available

AR GLASSFIBRE CHOPPED STRAND are packed in vacuum polythene bag. Each polythene bag is identified by an individual label. Chopped strands are white colored but an orange or blue color is used on labels to aid identification.

|

Product |

Strand length available(mm) |

Packing specification (mm) |

Net weight(kg) |

|

ARC15-98-XmmL(H) |

6、8、12、16 |

550×550×65 |

15 |

Pallet Packaging

1. Each pallet has 14 layers, 4 bags/layer, 20 pallets/20GP.

2. Each pallet with company label.

|

Product |

Length(mm) |

width(mm) |

Height(mm) |

Net weight(kg) |

|

ARC15-98-XmmL(H) |

1130 |

1130 |

1100 |

840 |

Shipment

20 pallets/20GP, and around 16 metric tons/20GP.

Storage

AR FIBERGLASS CHOPPED STRAND should be stored dry in their original package, the best conditions being at a temperature of between 15℃ -35℃ and at a relative humidity of between 35% -65%. If the product is stored at low temperature (below 15℃) it is advisable to condition in the workshop for 24 hours before use to prevent condensation.

Quality

All products are produced according to ISO9001:2008 quality control system.